Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

Minimum bend radius sheet metal aluminum metric.

Brittle metal such as aluminum generally requires a larger bend radius than ductile material like cold rolled steel.

Per the aluminum association inc.

The minimum bend radius data shown in these charts is measured to the inside of the bend.

We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.

Aluminum minimum bend radii for 90 degree cold forming of sheet and plate.

Minimum hole diameter guidelines.

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

5052 h32 aluminum bends in about the same way as mild steel.

It shall be equal to three times of sheet thickness plus bend radius.

The tool can calculate the required bending force for bending aluminum stainless steel mild steel and weldox or strenx high strength steels.

In steel between 0 5 and 0 8 in.

Minimum sheet metal flange bend length is required to avoid cracks in the bending area.

The minimum inside bend radius is even larger when bending with the grain.

It requires an inside bend radius of at least 6x the material thickness.

Bend radii minimum bend sizes.

Table 1 preferred recommended 90 degree bend radii for various sheet metals.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

This tool allows you to determine tonnage internal radius v die opening and minimum flange you just have to insert the characteristics of the sheet metal to be bent.

3003 h14 is extremely ductile.

Radii for various thicknesses expressed in terms of thickness t.

Recommended minimum bend radii for steel and aluminum.

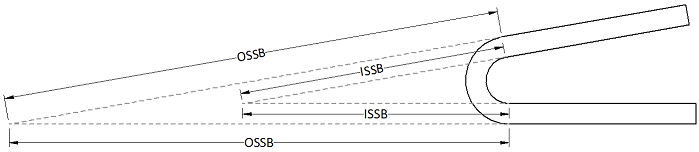

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

For example 6061 t6 aluminum is very difficult to bend.

It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness see figure 1.

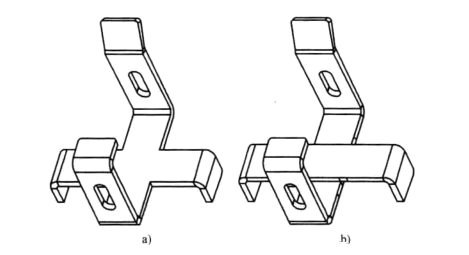

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

Discover all our calculation tools in the calculators section of the top menu.

Minimum sheet metal flange bend length 3 x sheet thickness bend radius.

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

Use this document to choose values that are both manufacturable and meet your needs.